PRODUCTS

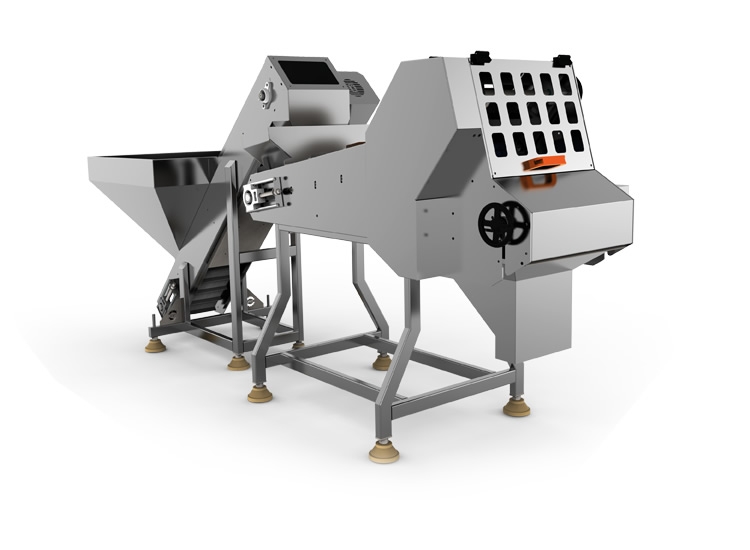

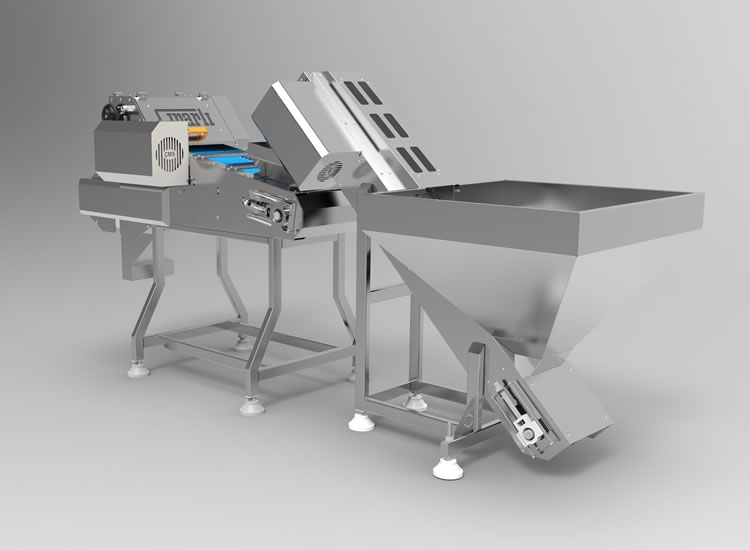

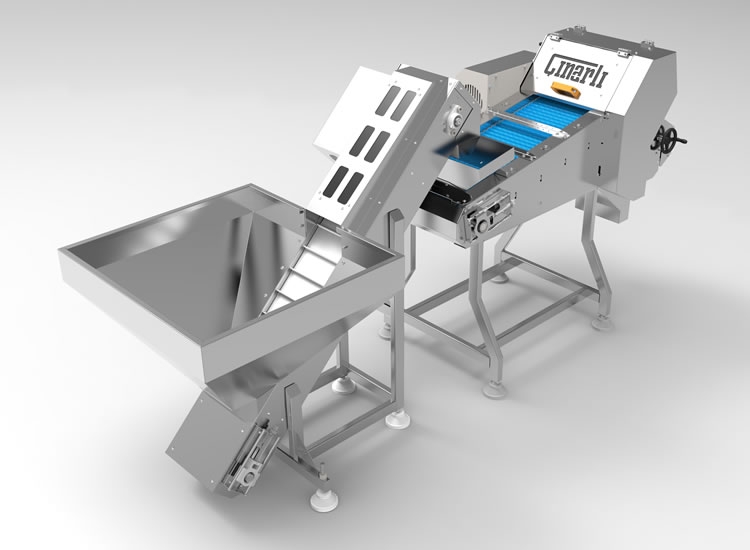

Olive Cracking Machine

Used in olive cracking process, the olive cracking machine first of all ensures a controlled scratch on olive for cracking process. For this, conveyor band transmits the olives horizontally to the blades with adjustable height. Horizontally transmitted olives are scratched in the middle. The scratched part of the olive which is stuck between two specially formed rollers with adjustable clearance is opened and made look like cracked by hand. As the damage occurring in olive during cracking process is minimized, strong olive shape is kept and it has a long shelf life.

- MODEL: CM010

- IP 65 plastic control panel (Hensel)

- 220 V / 50 HZ

- Electronic speed control system (Schneider)

- Automatic loading system with electronic speed control

- AISI 304L stainless steel body

- Bearings with plastic body and stainless steel housing

- Stainless steel blade

- Protection with thermic relay

- All the bands are made of PVC conforming to FDA

- Plastic based with AISI 304 stud feet

- Blade height adjustment mechanism

- Blade and roller washing system

- Rubber swivel rollers

- Adjusting the distance between rubber rollers and the blade

- Stainless steel belt chain

- Worm gear reducer

- Width 760mm

- Height 1265mm

- Water Consumption 100 lt/h

- Capacity (Min./Max.) 1000 kg/h

- Lenght (Machine + Elevator) 2775mm

- Quantity Of Blades 11 Units

- Engine Power (Machine + Elevator) 0,75 kw + 0,37 kw

Share This Page :